Thin-film solar panels use a 2nd generation technology varying from the crystalline silicon (c-Si) modules, which is the most popular technology. Thin-film solar cells (TFSC) are manufactured using a sing.

There are several types of materials used to manufacture thin-film solar cells. In this section, we explain the different types of thin-film solar panels regarding the materials u.

Before comparing the different types of thin-film solar panels against crystalline silicon solar.

Thin-film solar panels have many interesting applications, and they have been growing in the last decade. Below you will find some of the most popular application.

Thin-film solar technology might not be as popular as crystalline silicon, but it has an incredibly promising future. This technology opens possibilities that are not available for c-Si panels.

Thin-film technologies reduce the amount of active material in a cell. The active layer may be placed on a rigid substrate made from glass, plastic, or metal or the cell may be made with a flexible substrate like cloth. Thin-film solar cells tend to be cheaper than crystalline silicon cells and have a smaller ecological impact (determined from ).Their thin and flexible nature also.

Contact online >>

Jul 30, 2018· Thin-film panel manufacturer First Solar—exempt from the tariffs—is expanding its Vietnam manufacturing plant and will build a new 1.2-GW facility in Ohio to meet utility-scale demand. The expected 500 U.S. jobs will assist with production of the company''s new Series 6 module, which is sized and powered to be competitive with traditional c-Si.

Apr 30, 2018· Power-conversion efficiency is a key driver to reduce the cost of photovoltaic (PV) electricity 1.Tandem solar cells open a path to efficiencies above 30%, which exceeds the Shockley–Queisser

Dec 9, 2022· Popular Science reporter Andrew Paul writes that MIT researchers have developed a new ultra-thin solar cell that is one-hundredth the weight of conventional panels and could transform almost any surface into a power generator. The new material could potentially generate, "18 times more power-per-kilogram compared to traditional solar technology," writes Paul.

Jun 6, 2023· This is why scientists and leading solar panel manufacturers are developing flexible thin-film solar panels with high efficiency and sustainability. The flexible solar panel industry is growing fast in the USA due to consumers'' demand for this type of solar panel for camping, boating, and other outdoor activities.

May 17, 2024· Definition of Thin-Film Solar. Thin-film solar panels harness energy from direct sunlight using one or more thin layers, or a thin film of semiconducting materials placed on a suitable base such as glass, plastic, or metal.

Aug 25, 2014· Both rigid and flexible thin-film modules can be created, allowing solar generation to be better integrated into products and buildings compared to crystalline silicon. Thin-film solar panels are no longer available in most countries due to the higher cost and lower efficiency compared with the modern mono and polysilicon panels.

Aug 10, 2020· The thermoelectric modules fabricated with ITO (Ar) thin film and treated PEDOT:PSS thin film as the n-type and p-type thermoelectric legs, respectively, on both glass and PET substrates were

May 4, 2022· Like other solar panels, thin-film panels convert light energy into electrical energy by way of the photovoltaic effect. Unlike traditional systems, thin-film solar panels are very light

Among the most expensive thin-film panels is the CIGS thin-film panels. They''re made from Copper Indium Gallium and Selenide layers, and the substrate can be plastic or steel, depending on the intended use. Like other thin-film panels, CIGS panels have a lower efficiency rating of between 10-12%.

Feb 13, 2023· Compared to traditional solar panel cells holding most of the market share, thin-film solar panels include electricity-producing layers that are hundreds of times thinner than typical

Jan 8, 2020· 1.2 Photovoltaic technologies. The present PV technologies could be classified in two categories: (1) wafer-based (2) thin film cells ().Wafer-based cells are fabricate on semiconducting wafers and could be handled without an additional substrate, while modules are typically covered with glass for improving the mechanical stability and more protection.

Apr 3, 2007· The recent boom in the demand for photovoltaic modules has created a silicon supply shortage, providing an opportunity for thin-film photovoltaic modules to enter the market in significant quantities. Thin-films have the potential to revolutionise the present cost structure of photovoltaics by eliminating the use of the expensive silicon wafers that alone account for

Jun 6, 2022· Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film technologies account for a small but

Feb 7, 2024· Cadmium Telluride (CdTe), Copper Indium-Gallium Selenide (CIGS), and Copper Indium Selenide (CIS) comprise another important group of thin-film solar technologies.The record efficiency is set at 22.1% for CdTe, 22.2% for CIGS, and 23.5% for CIS.They also feature a highly competitive cost per watt ($/W).. Just like with other thin-film solar technologies, CdTe, CIGS,

First Solar''s thin film modules require only 1-2% of the semiconductor material needed by traditional c-Si modules to produce a comparable amount of power. The company''s vertically integrated manufacturing technology results in fewer process steps and faster production times with superior traceability and transparency.

Sep 18, 2023· Thin-film solar panels are photovoltaic solar panels made from thin layers of semiconductor materials deposited on a low-cost substrate, like glass or flexible plastics. They

PV MODULES COMPETITIVE? A: First Solar thin film modules are manufactured using a fully integrated and resource efficient process which enables affordable, high volume production with the lowest environmental impacts in the industry. In addition, First Solar''s high efficiency thin film modules are proven to deliver more usable energy per

Oct 22, 2024· Thin-film modules are available in both rigid and flexible versions, and you can find adhesive panels that easily attach to vertical and curved surfaces — like the roof of a camper van.

Mar 27, 2023· Here, the authors present a holistic numerical model, verified with real-world data of thin-film CIGS modules, that can conduct loss analysis and predict the energy yield of thin film solar cells.

Jan 13, 2016· However, state-of-the-art bulk thermoelectric modules have a maximum cooling flux qmax of only about 10 W cm−2, while state-of-the art commercial thin-film modules have a qmax <100 W cm−2.

Sep 15, 2024· CIGS thin-film solar panels currently hold only 1% of the market share, but the technology has been constantly growing in the solar industry since 2017, making it one of the most important thin-film solar technologies. It is expected that CIGS thin-film solar panel technology will keep on growing at a compound annual growth rate (CAGR) of 6.97%

Jul 1, 2018· In [20] the electrical behavior of single-curved thin-film modules is simulated and investigated. In [21] curved thin-film modules are modeled with a mixed 1D/3D approach with focus on optical modeling of the PV encapsulation material and module bending. They, however, only simulate for certain hours of the year and do not focus on partial shading.

Mar 19, 2022· The thin film solar cells with an average conversion efficiency of 30% (AM0) were connected together in series to increase the module''s voltage up to 500 V. Increasing module''s voltage allows to reducing the resistive losses during long distance current transportation and is enable inverter simplification leading to more efficient.

OverviewMaterialsHistoryTheory of operationEfficienciesProduction, cost and marketDurability and lifetimeEnvironmental and health impact

Thin-film technologies reduce the amount of active material in a cell. The active layer may be placed on a rigid substrate made from glass, plastic, or metal or the cell may be made with a flexible substrate like cloth. Thin-film solar cells tend to be cheaper than crystalline silicon cells and have a smaller ecological impact (determined from life cycle analysis). Their thin and flexible nature also

Other thin-film solar cell manufacturers are just as busy. Ohio-based First Solar is working with Juwi Solar to construct a 40-megawatt thin-film CdTe solar field in Saxony, Germany, that will be completed in 2009. And Honda is actively experimenting with building-integrated thin-film CIGS on a facility in Japan.

Sep 23, 2021· The TEL Solar from Switzerland showed the most prominence 12.3% efficient α-Si multi-junction business modules. In the thin-films industry, CIGS rigid substrate has the greatest eminence with a 19.2% commercialized module from Solar Frontier, Japan. One of the reputable CdTe companies, First Solar Inc., USA is manufacturing devices with the

Nov 17, 2023· Thin film photovoltaic modules or panels consist of layers of semiconductor materials like amorphous silicon, cadmium telluride, or copper indium gallium selenide.These photovoltaic (PV) solar cells are designed to harness solar energy efficiently. They are considered the future of the solar industry as they are economical and require less material, thus

Thin-film modules (as well as crystalline modules) may exhibit fault mechanisms that cause the modules to lose power over time. While crystalline modules can suffer from PID (Potential Induced Degradation), thin-film modules have irreversible mechanisms such as TCO corrosion. That means that module damage and the associated power losses cannot

The Thin Film Measurement Module is also easy to work with. It involves setting the transient temperature reading''s measurement time, output power, and prior knowledge of the film/coating thickness as input parameters. Film/coating samples of thickness ranging from 500 micrometers to 10 micrometers can be tested.

A High-Quality Thin Film CdTe Module Made in America, for America. Series 7 modules combine First Solar''s thin film cadmium telluride (CdTe) technology with a larger form factor and an innovative new back rail mounting system to deliver improved efficiency, enhanced installation velocity, and unmatched lifetime energy performance for utility-scale PV projects.

CIGS cell on a flexible plastic backing.Other architectures use rigid CIGS panels sandwiched between two panes of glass. A copper indium gallium selenide solar cell (or CIGS cell, sometimes CI(G)S or CIS cell) is a thin-film solar cell used to convert sunlight into electric power. It is manufactured by depositing a thin layer of copper indium gallium selenide solid solution on

Jul 30, 1999· They use a method for integrated monolithic series connection of submodules that is similar to the one developed for amorphous silicon and other thin-film modules. Efficiencies reported recently for a 320-cm 2 module are 9.79% . It can be expected that these methods will yield some cost advantage as compared to conventional wafer-based

Mar 6, 2022· The CIGS thin-film solar panel is a variety of thin-film modules using Copper Indium Gallium Selenide (CIGS) as the main semiconductor material for the absorber layer. This technology is being popularized for utility-scale installations, Building-Integrated Photovoltaics (BIPV), PV rooftops, flexible thin-film solar panels, and more.

Feb 7, 2024· Thin-film solar panel technology consists of the deposition of extremely thin layers (nanometers up to micrometers) of semiconductors on backing materials that provide the body

Thin Films: Materials Choices & Manufacturing Lectures 12 & 13 MIT Fundamentals of Photovoltaics 2.626/2.627 – Fall 2011 Prof. Tonio Buonassisi Some unique failure modes for thin-film modules (e.g., electromigration) New protocol for thin-film reliability testing: IEC 61853. Buonassisi (MIT) 2011

Researchers engaged in the Capitano project are combining thin-film solar modules based on perovskite semiconductors with semiconductors made of copper, indium, gallium and selenium (CIGS). This combination is the key to building remarkably efficient tandem solar cells with all the advantages of thin-film technology and an efficiency factor

Jul 1, 2018· In this work we present a simulation of performance of curved thin-film modules for building and product integrated photovoltaic applications. Flexibility of design and possibility of achieving irregular shapes is important feature in these markets. The photovoltaic module model presented in this work is based on a coupled two-step model.

Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials. These thin, light-absorbing layers can be over 300 times thinner than a

Aug 7, 2022· Disadvantages of thin film solar panels. Given the current state of solar panel technology, there are a few disadvantages of thin film solar panels. Lower efficiency compared to crystalline panels. However, since thin film panels have multiple p-n junctions, their theoretical limit surpasses that of crystalline panels. In other words, with more

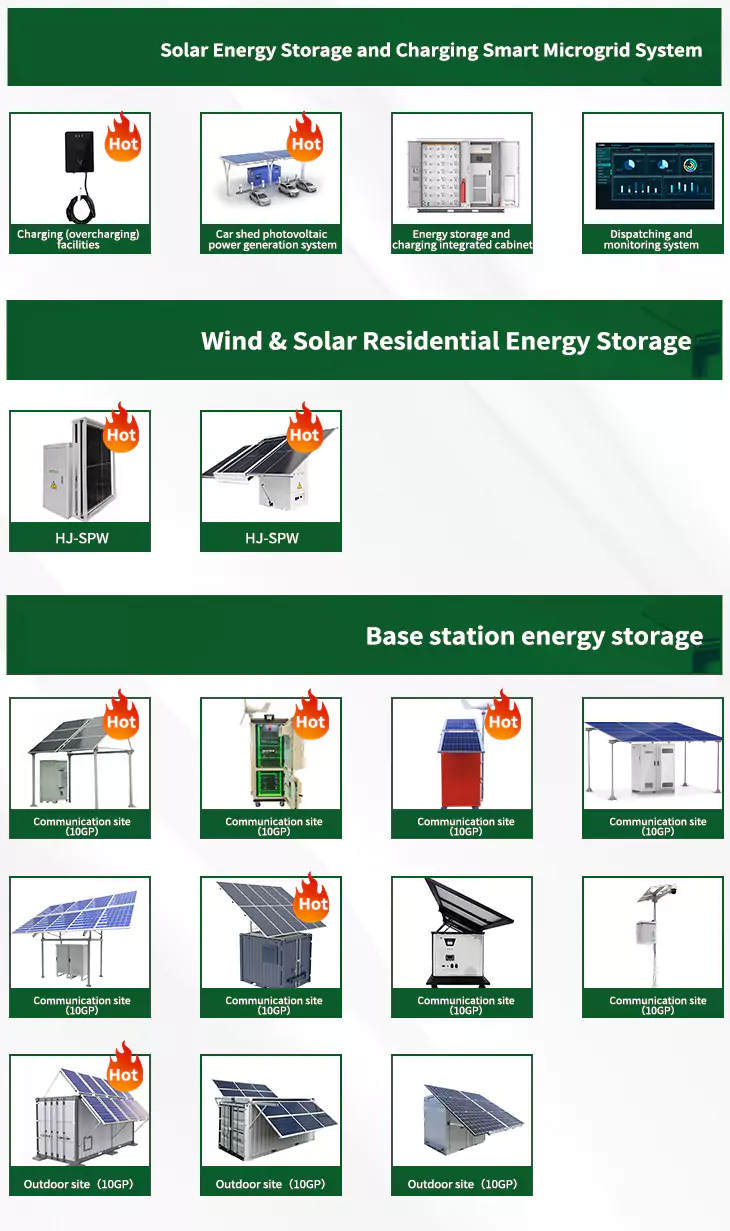

As the photovoltaic (PV) industry continues to evolve, advancements in thin film modules have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient thin film modules for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various thin film modules featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Enter your inquiry details, We will reply you in 24 hours.